Precision CNC Machined Parts and the Power of CNC Machining in Modern Industries

In today's ever-evolving manufacturing world, the need for precision, consistency, and speed has never been more critical. One technology that has revolutionized the way parts and components are created is CNC machining. Known for delivering impeccable accuracy and surface finish, CNC machined parts have found their place in some of the most demanding industries such as aerospace, automotive, robotics, medical devices, and oil & gas. With automation, flexibility, and tight-tolerance capabilities, CNC machining has shifted from being a niche to becoming a global manufacturing standard.

CNC (Computer Numerical Control) machining is a subtractive manufacturing process. It utilizes pre-programmed computer software to dictate the movement of factory tools and machinery. From lathes and mills to routers and grinders, CNC machines carve out parts from raw materials like stainless steel, aluminum, brass, and engineering-grade plastics. This electronic method ensures that parts are manufactured to exact specifications every time, making CNC machining indispensable for applications where precision is non-negotiable.

The primary advantage of CNC machined parts is their consistency. Traditional manual machining leaves room for human error, especially when working with complex geometries or high-volume orders. CNC machines, however, follow digital instructions with microscopic precision, ensuring each part corresponds the last. This repeatability is a game-changer for industries that need perfect components over long production runs.

Another standout feature of CNC machining is its ability to produce detailed shapes that would be difficult, if not impossible, to achieve by hand. With multi-axis setups, CNC machines can turn and navigate in different directions, enabling them to create complex cavities, sharp internal angles, and smooth curves-- all in a single setup. This capability greatly reduces the need for numerous components, manual repositioning, and post-processing.

Industries such as aerospace rely heavily on CNC machined parts due to the extreme performance standards they demand. Parts like turbine blades, engine brackets, and housing structures must be light-weight yet strong, resistant to environmental stress, and machined to tight tolerances. Likewise, in the medical sector, implants, surgical instruments, and diagnostic equipment must be crafted to exacting standards to ensure safety and functionality.

The automotive industry also takes advantage of CNC machining's ability to manufacture gear real estates, engine blocks, brake system parts, and custom prototypes. These components are anticipated to perform under high stress, and any variance in dimensions can lead to performance deterioration or system failure. CNC machining provides the dimensional accuracy needed to keep these critical systems running reliably.

Robotics and automation sectors depend upon CNC machining for components such as mechanical joints, precision brackets, and linkages. As robots become more advanced and tasks become more specialized, their parts must provide high mechanical strength, low weight, and flawless function. CNC machining provides the flexibility to meet these developing design requirements without compromising toughness.

Beyond performance, CNC machining is also known for its outstanding surface finish. High-speed spindles, precision-cutting tools, and the right feed rates can produce parts that often require little to no finishing after machining. This efficiency not only conserves time however also decreases costs and improves throughput.

In the global supply chain, India has emerged as a powerful player in CNC machined parts production. The country offers a blend of cost-effective manufacturing, skilled labor, and advanced technological infrastructure. Among the business contributing to this rise is Robocon CNC Pvt. Ltd., a precision engineering company located in Pune, India.

Robocon CNC sticks out by providing world-class CNC machining services with a focus on quality, dependability, and customer complete satisfaction. With a state-of-the-art facility real estate advanced CNC and VMC (Vertical Machining Center) machines, Robocon CNC is fully equipped to meet the demands of industries around the world. Their team of experienced engineers ensures that every project-- from model to high-volume production-- is executed with precision and speed.

What sets Robocon CNC apart is their ability to handle high-complexity components that need tight tolerances and demanding geometries. Their offerings include machining CNC machined parts of stainless-steel, aluminum, brass, and other exotic materials often used in defense, aerospace, and energy sectors. With a robust quality management system aligned with ISO standards, the company guarantees consistency in every shipment.

For businesses looking for dependable suppliers for CNC machined parts, the decision often comes down to quality assurance, turn-around time, and cost. Robocon CNC provides on all these fronts. The company's ability to scale production, satisfy global shipping deadlines, and deal engineering support makes it a favored choice among OEMs and start-ups alike.

Another element contributing to the efficiency of CNC machining at Robocon CNC is the use of CAD and CAM (Computer-Aided Manufacturing) software. These tools enable the creation of virtual models and simulations, which are used to tweak designs before production. This decreases material waste, reduces production time, and eliminates unneeded iterations. It's a smart manufacturing technique that benefits both the supplier and the customer.

Robocon CNC also embraces innovation. Their team constantly buys process optimization, machine upgrades, and operator training. As the industry approaches Industry 4.0, business like Robocon CNC are at the forefront of executing smart manufacturing practices-- leveraging data analytics, IoT sensors, and automation to ensure much better decision-making and real-time monitoring.

With increasing global demand for reliable and competitively priced CNC machined parts, the significance of partnerships with capable suppliers is greater than ever. Makers in the USA, Europe, and Southeast Asia are actively outsourcing components to Indian firms, recognizing the country's capabilities in precision engineering. Robocon CNC, with its tested track record, is helping bridge the gap in between design innovation and production excellence.

Moreover, the advantages of CNC machined parts extend beyond simply industrial applications. These parts are increasingly being used in product development and R&D environments where models must match final product performance. CNC machining enables quick turn-around, which speeds up testing and shortens product development cycles. For start-ups or entrepreneurs, this is a crucial benefit that helps with much faster time-to-market.

In the world of sustainability, CNC machining also reveals guarantee. Unlike additive manufacturing which often leads to lose from failed prints or assistance materials, CNC machining-- while subtractive-- can be enhanced for material usage through smart nesting and toolpath strategies. Numerous CNC stores, including Robocon CNC, focus on recycling chips and scrap material, adding to eco-conscious manufacturing.

As the demand for premium CNC machined parts grows, the role of precision machine shops becomes significantly critical. Companies that provide not simply machining, but a complete option-- right from engineering assistance to logistics-- will stand out in the competitive landscape. Robocon CNC exemplifies such a company, providing value-driven services that satisfy global expectations.

For engineers, designers, and makers, CNC machining offers an effective service for bringing ingenious ideas to life. Whether the requirement is for an easy bracket or a complex aerospace component, the advantages of CNC machining-- precision, repeatability, versatility, and scalability-- stay unrivaled.

Conclusion: .

CNC machined parts continue to improve the modern industrial landscape with their unmatched precision, reliability, and adaptability. As global industries promote better quality and faster production cycles, CNC machining has shown to be a basic enabler. Companies like Robocon CNC Pvt. Ltd. are leading the charge, providing innovative solutions that deal with both local and global markets. With robust infrastructure, technical expertise, and a commitment to excellence, Robocon CNC represents the promise of India's growing manufacturing capacity. As industries evolve, the significance of relied on CNC machining partners will just become more significant, and Robocon CNC is well-positioned to satisfy those demands with self-confidence.

Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Hailie Jade Scott Mathers Then & Now!

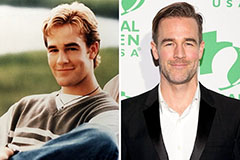

Hailie Jade Scott Mathers Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!